Bring your Project to Life with Rapid Prototyping Services

Eliminate the guesswork and unlock the full potential of your thermoformed plastic projects with New Plastics Plus. Our sleek and professional team is dedicated to providing rapid prototyping solutions that bring your vision to life with exceptional precision.With our highly experienced experts in thermoforming, we offer detailed and accurate rapid prototypes tailored to your exact specifications. We understand the importance of replicating the scale and structural properties of your products, ensuring that every prototype perfectly represents your intended design.

As an ISO 9001:2015 certified thermoformer, we uphold the highest standards of quality. Our commitment to excellence drives us to find the best manufacturing solution for your pattern or part, ensuring optimal functionality and durability. With our cutting-edge in-house prototyping capabilities, we guarantee both superior quality and efficient turnaround times. We harness the power of advanced technology to bring your thermoformed plastic parts to life with unrivaled speed and precision.

Contact us today to discuss your requirements and experience the seamless journey from rapid prototyping to a successful final product.

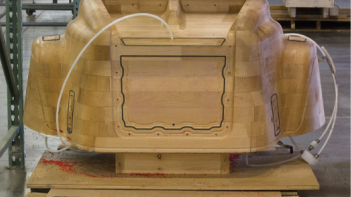

Precision CNC Machining

Experience seamless plastic thermoforming projects with New Plastics Plus, where cutting-edge technology and a dedicated team come together to deliver exceptional results. Our advanced in-house facilities enable us to provide rapid prototyping solutions that exceed expectations.

With state-of-the-art thermoplastic molding machines and sophisticated CMS 5-axis CNC machines, we have the capabilities to create prototypes with unmatched precision and meet the tightest tolerances. From concept to production, our experienced project engineers ensure deadlines are met and precise specifications are achieved, offering you a seamless start-to-finish experience.

Rapid Prototyping

Our prototype development and machining team will work tirelessly with your team to create an end product that will fit your needs. Our rapid thermoformed prototyping process allows for the efficient and cost-effective production of prototype parts in a short period of time. This process enables your designers and engineers and our team of experts to quickly evaluate and test the functionality, fit, and form of a product before committing to full-scale production.

Accelerated Product Development

The Rapid thermoforming plastic process allows for faster product development cycles at NPP. Design iterations can be quickly produced and tested, speeding up the design refinement phase that bring products to market more quickly.

Learn More

Cost-Effective Prototyping

Plastic thermoforming and efficient 5-Axis Interpolated CNC cutting offers a cost-effective solution for producing prototype parts. Rapid-Prototyping reduces material waste and setup times which contributes to overall cost savings.

Learn More

Efficient Design Validation

Thermoformed plastic prototypes provide an accurate representation of the final product. Physical prototypes allow for thorough design validation, testing fit, form, and functionality. Early detection and resolution of design issues help minimize potential production delays and costs.

Learn MoreRapid Prototyping

Experience shorter timelines, reduced costs, and accurate representation of your final product. Unlock the potential of this innovative manufacturing process and propel your product development journey forward. Use New Plastics Plus for your next Vacuum Thermoplastic project.

Request a quote

Let’s connect! Contact us by email, phone, or visit our state-of-the-art facility in St. Michael, MN. We’re excited to work with you.

About New Plastics Plus